Sensory Evaluation for Aging Spirits

by andrew wiehebrinkSensory evaluation is one of the best parts of my job. It is as enjoyable as it is interesting and most importantly, it is absolutely necessary for quality assurance and new product introduction. Any person or any business involved with food or beverage production, whether it be alcoholic beverage production or not, should have a sensory protocol in place for evaluating experiments. Sensory programs come in a lot of different formats and from what I have seen, the structure depends on two things:

- The overall goal of the analysis

- The amount of personnel, time, and space available

Today, I thought I might describe what the protocol looks like for Independent Stave Company’s spirits research department. This isn’t going to be a ‘how to’ blog post more so than it is a post describing what we look for and the scale to which we evaluate our samples. There are a lot of books on sensory evaluation that are good at explaining the entire process from setup to evaluation. However, a word of caution…while I encourage you to read these books before setting up a panel, I also encourage you to realize that you need to find your own way of doing things at your distillery. Proper sensory analysis is a very time consuming and expensive procedure. Many startup distilleries are not going to have the people, space, time, or budget to implement a ‘by-the-book’ sensory operation. AND THAT IS OKAY, but there should be a procedure in place! Even if all you can spare is yourself and an hour each week, the main thing is that the protocol is consistent and gives you the data set or results you need.

Side note: One of the things that is severely lacking in the distilled spirits industry is a universal standard for evaluating samples. Whether it be sensory or chemical analysis, everybody seems to do things a little different which makes evaluation between entities challenging.

When designing your sensory program, the first thing you should be thinking about is “What am I trying to accomplish?”. What data, if any, do you need to bring in. I have been to several distilleries in which no data is obtained in their sensory analysis of new make liquid. They will simply lay out distillate samples from each fermenter and compare them against a sample of approved quality and have their sensory team evaluate each fermenter sample to say if it’s different from the standard. It is basically a ‘yes or no’ evaluation. And that works for them.

At ISC, we are evaluating barrel performance and flavor delivery for all of our barrels in experiment. As such, our evaluations need to be a bit more in-depth because we are critiquing a flavor progression, sometimes across several years. The way we do that is by looking for flavors that are indicative of a specific barrel extractive or by looking at flavors that aren’t necessarily from the barrel but that a barrel can mask…like grain or esters.

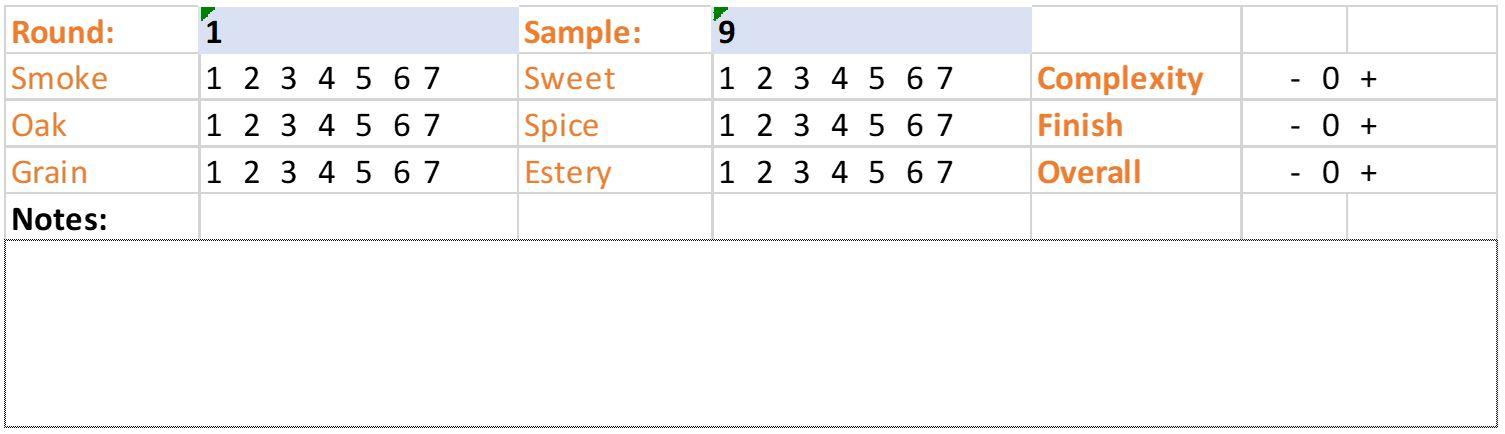

Panelists are trained to detect these flavors and/or aromas and rate them on a scale between 1 and 7. Our scoring sheet is shown in figure 1.

The first thing people notice is that we are doing quantitative analysis and not descriptive analysis. The reason goes back to our overall goal. It is very difficult to track performance of the barrels year after year using only descriptors. If we are looking at how flavors progress over an extended period of time, quantitative analysis is necessary. This is difficult to learn in the distilled spirits space but again, necessary for obtaining the data we need and making it meaningful and useful.

The second thing some folks notice is the simplicity. Your sensory program doesn’t need to be confusing. It needs to have the minimum number of parameters possible to give you the data that you need. We do not give our panelists the freedom to choose random descriptors. That makes sensory very difficult. Almost like doing a word search puzzle without the list of words. It is much easier to look for something if you know what you are looking for before you start evaluating.

Even though our descriptors are simple, they tell us quite a bit about the sample we are evaluating if we assume some basic knowledge about oak, aging, and extraction kinetics.

- Smoke – Marker for compounds such as guaiacol

- Oak – Marker for tannin

- Grain – Marker for barrel impact and whiskey age

- Sweet – Marker for compounds such as vanillin

- Spice – Marker for compounds such as eugenol

- Estery – Marker for barrel impact and oxygenation

We also gauge the complexity, finish, and overall quality.

For a distillery, this sheet might look very different. I find that while we look for quality as a function of specific desirable flavors, many distilleries seem to look for quality as a function of specific faults. Again, it just goes back to what you need to know and designing your program to deliver the information as easily as possible.

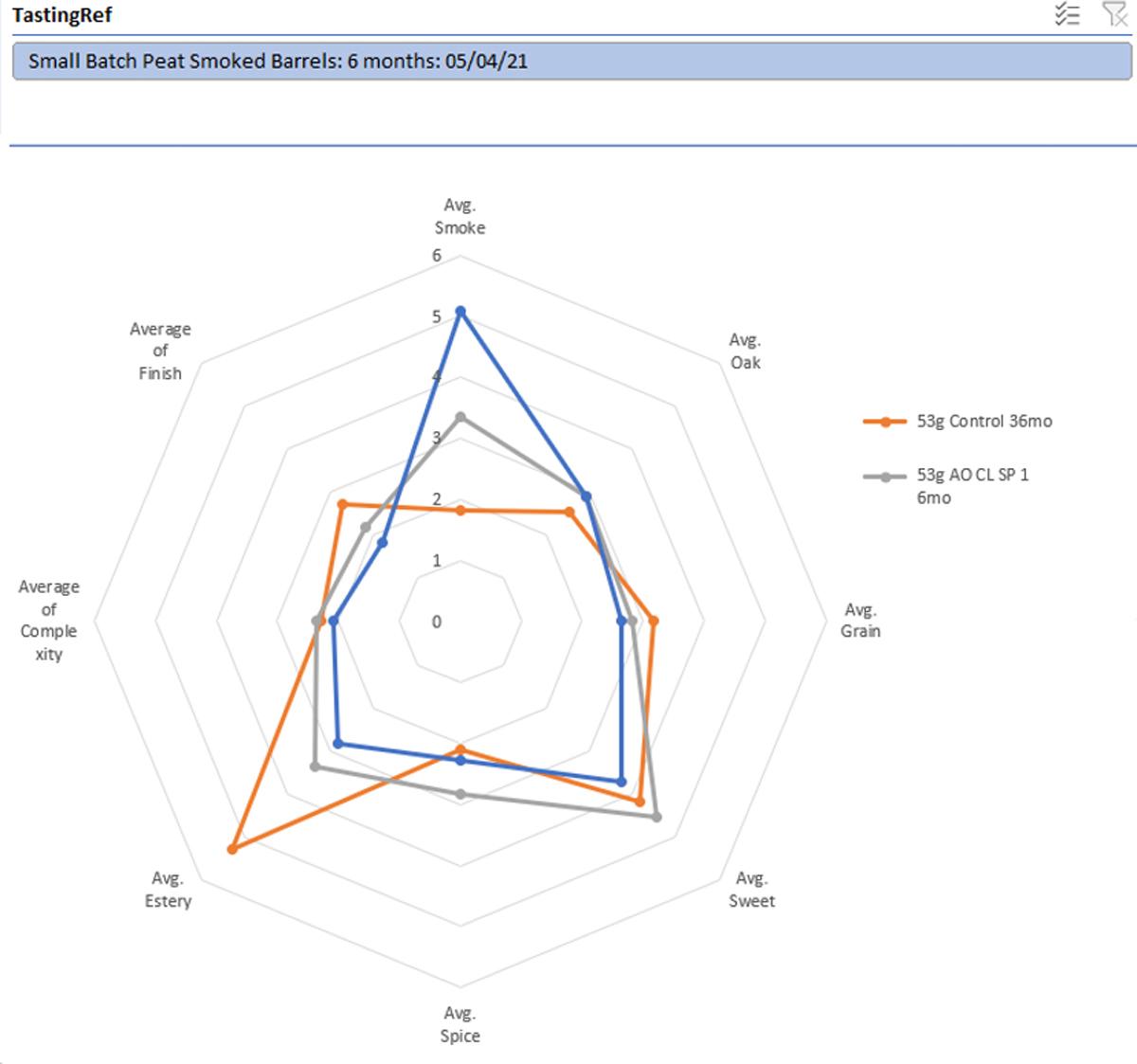

Once we have gathered all the data from our panel, we use a simple excel program to evaluate all the results. There are some nice sensory software suites available, but they can be costly. By using excel, we were able to get our program developed using little time and money and it is customized to our exact needs. We still have to input the results manually but that really is the only downside. For each sample that our panelists evaluate on paper, the program returns a report as shown below in figure 2.

The sensory results are stored in the cloud, and we can call up the results whenever we need to look at how specific barrels performed in different scenarios.

I hope this post has been informative and gave you an entertaining glimpse into how we evaluate our experiments here at the Kentucky Research Center. If you have any questions, feel free to send me an email.

Cheers!

Andrew