Barrel Profiling - Part II

In Barrel Profiling – Part 1, we touched on a few topics relating to the heat treatment of oak barrels. Specifically, we outlined the unique benefits of ISC’s barrel profiling system and the effects it can have on flavor development in oak-matured spirits. In this post, we will dive deeper by analyzing the results of a recent ISC experiment which utilized profiled barrels.

Barrel Experiments: Each year the Independent Stave Company Research and Development team conducts in-house experiments, laying down hundreds of experimental barrels in order to further understand oak maturation. Our experiments look at elements such as oak species, tree growth rate, length of wood seasoning, and the differences in extraction kinetics between alcohols of different proofs.

In this experiment, we took a blend of four to six-year old bourbon whiskey and applied a secondary finish using profiled and charred barrels. The goal of this experiment was to alter and enhance the quality of the base spirit in a short amount of time. For this trial, we finished the four to six-year old whiskey in new barrels for six weeks. We collected samples each week and monitored the process using both chemical and sensory analysis. The three barrels listed below were used in this experiment.

Our Classic Whiskey barrel features wood seasoned three to six months before being constructed into a barrel. Cooper’s Select barrels are made of wood seasoned eighteen months. Air seasoning is important to flavor development because it provides time for the wood constituents to break down. When these wood constituents (e.g. lignin and hemicellulose) are broken down prior to being toasted or charred, the end result is a greater concentration of aromatic compounds – such as furfurals and vanillin – born from the heat treatment process. In addition, wood tannins begin to soften and the wood becomes less acidic. Both processes influence flavor development. Depending on the product being produced, that influence can be positive or negative. Hint: think about what happens when acids react with alcohols.

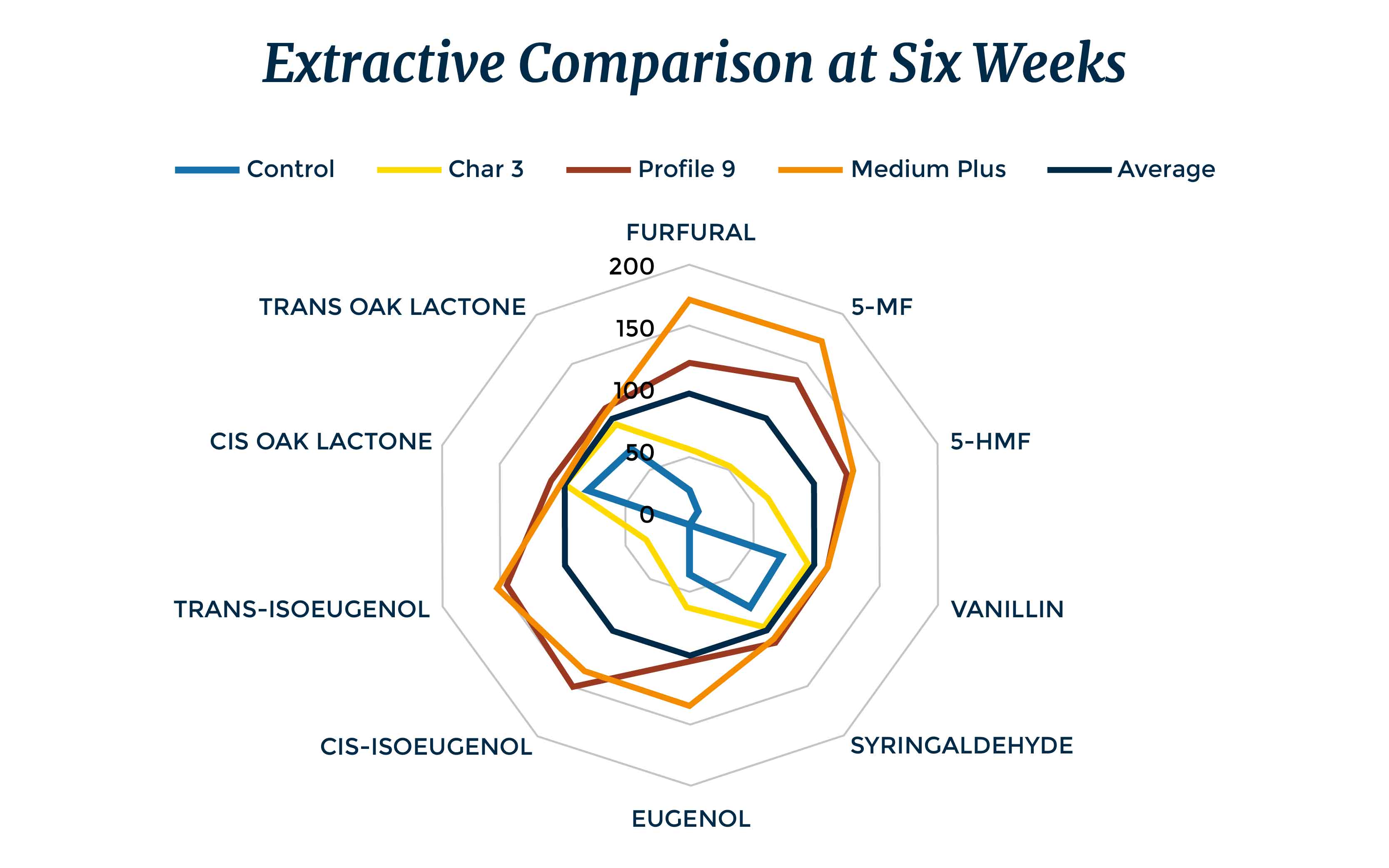

Figure 1 below shows each barrel’s performance after six weeks of finishing. The control is simply the four to six-year old bourbon whiskey we used as our base spirit with no secondary finishing. This base spirit was aged in our Classic Whiskey barrel with a level 3 char.

It is important to note that the comparison represented in Figure 1 does not show actual concentration levels of extractives in terms of mass per unit volume. What it does show is a percentage of extractives compared to the average across all treatments. This provides an easy to understand overview of barrel performance but if you are looking at this in terms of extraction kinetics, it can be a little tricky to interpret.

There is a spike in furfurals and eugenols across all barrels. Due to the nature of extraction kinetics, these are among the first compounds to be absorbed into the whiskey during maturation. Different toasting profiles will influence the creation and destruction of extractives and odorous components in different ways. This can be observed in figure 1 by comparing the concentrations among the profiled barrels.

We filled these barrels in the middle of December and only allowed them to sit for six weeks. If we had let them sit longer or perhaps filled them in the warmer months, we would see greater differentiation between the profiled barrels. Due to the short contact time and cold warehouse temperatures, the extractives that found their way into the whiskey were those residing near the surface of the stave. This also explains why we see a lesser concentration of extractives in the char #3 barrel. Like toasting, charring also creates a red layer rich in extractives. However, the heat from the charring process is so intense that a layer of carbon is formed on top of the red layer. The whiskey must first seep past this layer of carbon to access the flavorful extractives.

An interesting sensory note: Sensory analysis on the char #3 barrel indicated that for the first three weeks of finishing, this barrel cleaned up the spirit. Which depending on perspective could be a useful observation to keep in mind. While the complexity and aromatics were not as prevalent, the whiskey was perceived as smoother and cleaner. This could be useful for distillers looking to mellow product or remove undesirable compounds created by errors in distillation or fermentation.

Figure 2 is an extractive progression over the six-week period.

We can see from this graph the flavor profile of the whiskey changed very quickly in the toasted barrels – Profile 9 and Medium Plus. At week two, furfural levels were relatively equal. After six weeks in barrel, the medium plus barrel exhibits furfural levels 39% greater than the profile 9 barrel. So even in the colder months with short finishing times, each barrel induced a change in the base spirit and we were able to see distinction between each barrel.

When using secondary finishing, be sure to consider all the variables at play to accurately predict and achieve the desired flavor profile. Chemical analysis shows that extractive concentrations change quickly and sensory analysis reveals the favorite barrel at two weeks might not be the favorite at six. For your first effort in finishing, monitor the process each week. Your ideal product might appear in three weeks and be gone at six.

Cheers!

Andrew

About the Author - Andrew Wiehebrink

Andrew joined the Independent Stave Company team as the head of Research and Development in early 2016. His primary focus is working with ISC customers to develop and test new products. He will also design experiments to gather data on whiskey maturation, barrel performance, process and product innovation.

As a self-described, "bourbon fanatic" Andrew enjoys drinking and studying the history of bourbon. He also owns and operates a farm in Oldham County Kentucky that develops custom corn breeds for use in distilling.