Inside the Lab: Setting the Stage for Barrel Innovation

By ISC Barrels

Starting in the 1990s, we began an ongoing investment into oak research in conjunction with the late Dr. Jim Swan, an expert in whiskey and oak maturation. We brought together industry experts from around the world to review existing research and explore the latest innovations in spirit barrels. At the same time, we established partnerships with distillers to test our newest barrel advancements in real-world trials.

More than three decades later, we have not stopped pushing the limits in oak research and innovation.

Worldwide Research Centers

The art of crafting barrels has evolved into a precise science, thanks in part to our world-class Research and Development team. Operating out of cutting-edge facilities in Kentucky, California, and France, this team has played a key role in advancing barrel technology.

In 2017, we opened the Kentucky Research Center to expand our efforts in the heart of bourbon country. With state-of-the-art laboratory equipment, nearly all our data is now generated internally. Our multifaceted team of scientists and engineers collaborate directly with spirits industry professionals, continuously pushing the boundaries of barrel innovation through a deep understanding of oak’s chemistry and its interaction with spirits.

Key Areas of Research

The science of oak and spirits maturation is incredibly complex. Many factors can influence the result and thus are inherently all of interest to our research and development team- from exploring the impact of oaks species, wood age, oak product format, charring and toasting methods (ex: fire, infrared and convection) to how the characteristics of a spirit will also influence final harmony with the oak.

Our collection of research, as well as experiments yet to be released, are designed to pursue key goals relevant to distillers around the world:

- Oak product innovation

- Application of new technology and methodology

- Product selection according to targeted distillation goals

- Practical guidance to best utilize oak barrels and oak alternative products to achieve the desired flavor profile

Methods and Equipment

While our research and development team use an ever-increasing set of technology and equipment, key processes for many experiments include the use of:

- GCMS: Gas chromatography-mass spectrometry (Oak aromatics)

- HPLC: High performance liquid chromatography (Phenolics and tannins)

- SPME: Solid-phase micro-extraction (Aromatics and quality control)

- ASE: Accelerated solvent extraction (Solid/liquid extraction)

- UV-Vis Spectrometer (Color, phenolics and tannins)

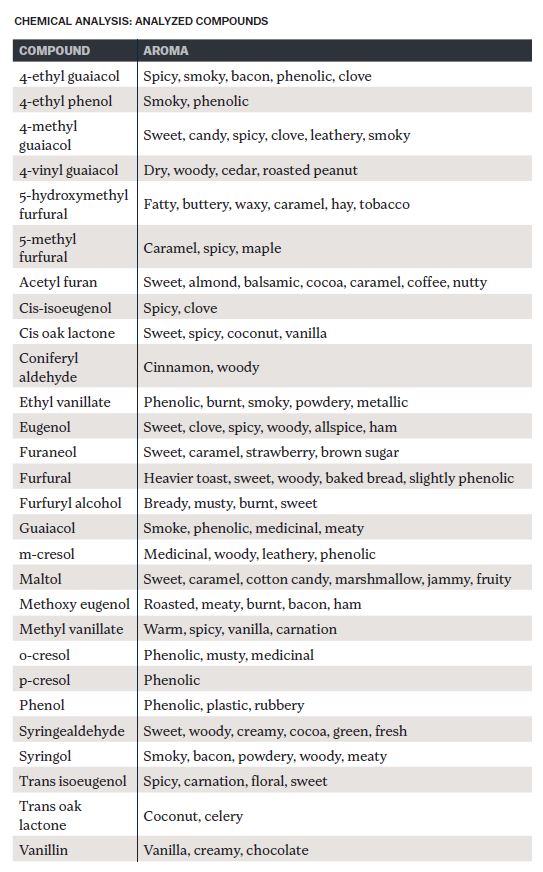

As part of the ongoing research, many compounds (shown below) may be analyzed to provide key insights.

Sensory Analysis

Sensory analysis can be time consuming and even expensive, but it is nevertheless an important way to evaluate experiments and the evolution of aromas, flavors and mouthfeel.

The ISC Research Center Sensory Panel allows us to conduct sensory research for experiments in markets around the world and specifically focuses on the influence of oak in spirits. Protocols are in place to ensure consistency and to achieve the type of data set that will be most helpful to the goals of an experiment. Panelists are trained to detect aromas and flavors that are key to the influence of oak in spirits. Examples include:

- Smoke – Marker for compounds such as guaiacol

- Oak – Marker for tannin

- Grain – Marker for barrel impact and whiskey age

- Sweet – Marker for compounds such as vanillin

- Spice – Maker for compounds such as eugenol

- Estery – Marker for barrel impact and oxygenation

In addition to rating aromas and flavors, the panel also gauges complexity, finish and overall quality.

A key focus on quantitative data allows the panel to better track flavor progressions over time, including several years. Qualitative data may also be tracked to confirm findings, but the quantitative data has proven most useful in identifying patterns and progression over the chosen time period.

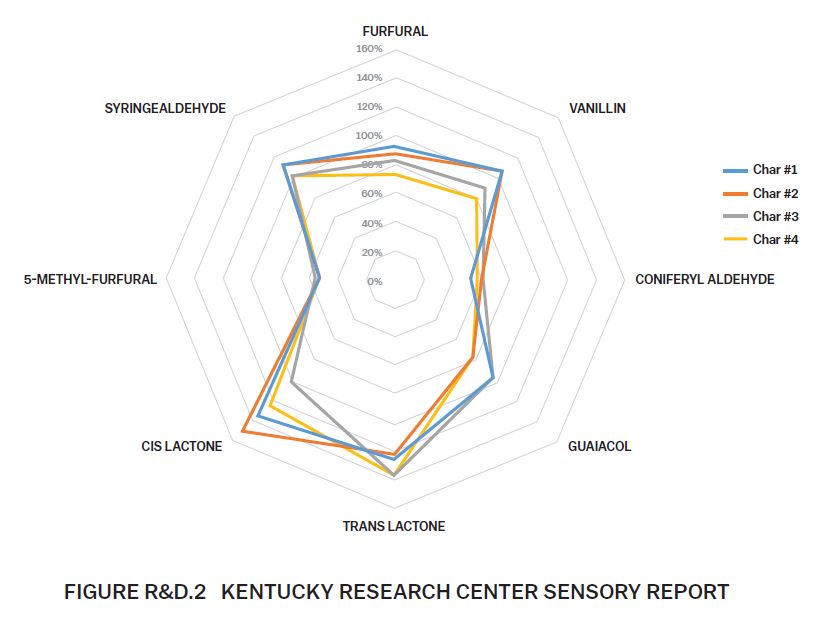

Once the data has been gathered, results are evaluated and presented in the form of a spider graph, as shown in Figure R&D.2 below.

Barrel Solutions for Unique Spirits

Our collaborative approach ensures that our innovations meet the unique needs of distillers worldwide. By investing in these experiments, we help producers achieve their desired sensory outcomes. As one distiller partner shared, “ISC’s ability to customize barrels to our exact flavor goals has been transformative.”

With our more than 30 years of oak research, we continue to lead the industry in innovation and sustainability. Our commitment to R&D not only enhances the artistry of barrel-making but also provides a crucial advantage for distillers. Combined with our perpetual curiosity around how spirits can be affected through oak drives our mission for exciting new research that craft spirits and captivate palates.